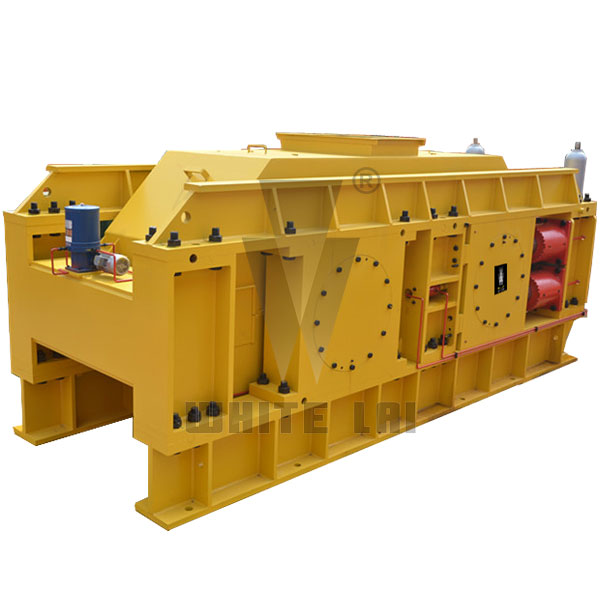

Hydraulic double-roll crusher is a kind of double-roll crusher. It is named because its main crushing part is composed of two rollers. The roller crusher is simple in structure and can be used for medium and fine crushing of medium-hard and soft ores. The roller crusher has many advantages such as finer crushing particles, larger capacity, simple operation, long service life, adjustable discharge particle sizes, and wide applications.

Applications:

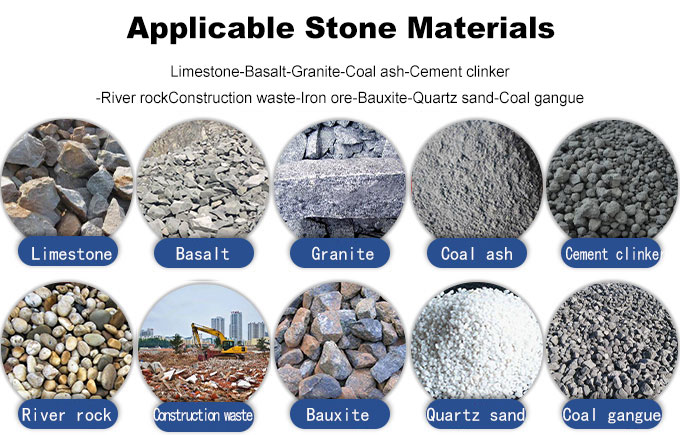

The hydraulic double-roll crusher is suitable for the medium and fine crushing of solid materials with a compressive strength lower than 300Mpa and a moisture content less than 35%, such as iron ore, quartz stone, potassium (sodium) feldspar, limestone, river pebble, and metal Silicon, barite, basalt, granite, steel slag, cement clinker, construction waste (concrete), shale, quicklime, coal, coke, clay, bentonite, chemical raw materials, etc. It can be widely used in mining, thermal power, cement ceramics, metallurgy, chemical industry, building materials and other industries. It has many advantages such as low operating cost, low moisture requirement, reliable performance, low power consumption, low dust and low noise.

Advantages:

• Compact structure • Efficient and energy-saving

• Large crushing ratio • Good crushing effect

• Upgraded system • Automatic hydraulic system

• Thickened roller skin • Long service life

• Hydraulic-spring integration, balanced flashback protection

• The discharging granule is full, the gradation is reasonable, and the powder content in the finished product is low.

• The hydraulic roller crusher has a low loss rate of wear parts, and the roller sleeve is made of manganese-chromium alloy steel with a long average service life.

Working principle and structure

1. This series of roller crushers are mainly composed of rollers, roller supporting bearings, pressing and adjusting devices, driving devices and so on.

2. Adjustment of the discharging granularity: a wedge or gasket adjustment device is installed between the two rollers, and an adjustment bolt is installed on the top of the wedge device. When the adjustment bolt pulls the wedge up, the wedge pushes the movable roller away from the fixed wheel, which means the gap between the two rollers becomes larger, and the discharging granularity becomes larger. When the wedge is downward, the gap between the two wheels of the movable roller becomes smaller under the action of the compression spring, and the discharging granularity becomes smaller. The gasket device adjusts the discharging particle size by increasing or decreasing the number or thickness of the gasket. When the gasket is increased, the gap between the two rollers becomes larger, and when the gasket is reduced, the gap between the two rollers becomes smaller and the discharge particle size becomes smaller.

3. The driving mechanism is composed of two motors, which are driven by a V-belt to the pulley to drag the roller, and rotate in relative direction. When crushing material, the material passes through the roller from the feed port, being crushed through rolling, and then crushed product is discharged from the bottom of the chassis.

| Model |

Roller diameter

(mm)

|

Roller width

(mm)

|

Max.feeding (mm) |

Capacity

(t/h)

|

Power

(kw)

|

Adjustable range of discharge opening (mm) |

Protection method

|

Transmission method

|

| 2PGT400x250 | φ400 | 250 | ≤25 | 2-10 | 2x5.5 | 0-8 |

Spring-protected Double-roll crusher |

V-belt driving |

| 2PGT600x400 | φ600 | 400 | ≤25 | 5-20 | 2x15 | 0-8 | ||

| 2PGT700x400 | φ700 | 400 | ≤30 | 10-30 | 2x18.5 | 0-10 | ||

| 2PGT800x500 | φ800 | 500 | ≤40 | 20-40 | 2x30 | 0-10 | ||

| 2PGT1000x800 | φ1000 | 800 | ≤40 | 45-80 | 2x45 | 10-150 |

Hydraulic Double-roll crusher |

Coupling driving |

| 2PGT1200x1000 | φ1000 | 1200 | ≤400 | 50-120 | 2x75 | 20-150 | ||

| 2PGT1200x1200 | φ1200 | 1200 | ≤400 | 80-150 | 2x90 | 20-200 | ||

| 2PGT1500x1000 | φ1500 | 1000 | ≤500 | 120-180 | 2x110 | 20-200 | ||

| 2PGT1800x1000 | φ1800 | 1000 | ≤500 | 150-230 | 2x160 | 30-300 | ||

| 2PGT2000x1000 | φ2000 | 1000 | ≤700 | 320-350 | 2x200 | 30-300 |

-

Agency and agent all ovr the world

Agency and agent all ovr the world

White Lai have many office in main market , and services to the customers face-to-face. -

Wear parts supply whole year

Wear parts supply whole year

White Lai with most professional wear parts supply system,to meet the market demand for services effectively.

-

The top services to you

The top services to you

White Lai's after-service number is 0086-21-68768882, 24 hours technical support by e-mail, by phone. -

The first-class customer service

The first-class customer service

If needed,experienced technicians guidance is available anytime. -

Technical support whole day

Technical support whole day

White Lai has service team , guidence with maintenance , spare parts , technical service work ,ect.

Leave message

Please Feel free to give your inquiry in the form below.We will reply you in 24 hours.