- Improved efficiency and throughput

- The unmatched producer of superior concrete and asphalt aggregate

- A proven producer of quality manufactured sand

- The only viable crusher for extremely abrasive fine material

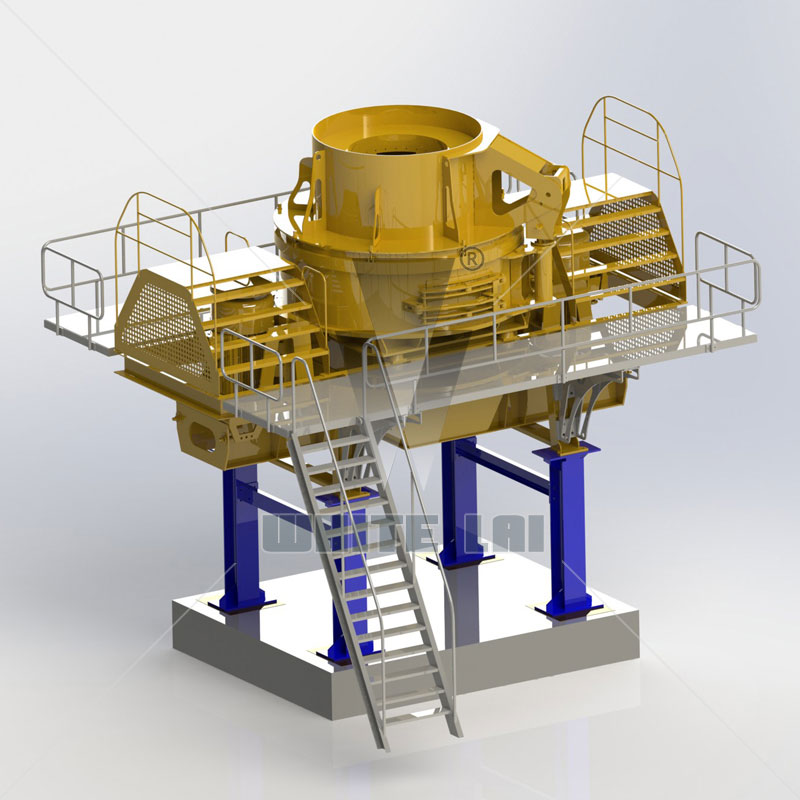

- The User-Friendly VSI crusher

- The cascade feed system

The cascade feed system provides:

• Higher crusher throughputs for the same power consumption.

• Maximum use of available power without fear of motor overload.

• Gradation control to optimise product fractions.

• ‘Free’ crushing at no extra expense to the operator.

• Shape control.

Applications:

Mining, metallurgy, construction, highway, railroad, and water conservancy, etc.

The S Series Vertical Shaft Impact(VSI) crusher was improved on basis of the technology of Barmac,it has had a huge impact on the global quarrying and minerals processing industries. The Barmac S-Series VSI is unique due to its crushing process. Whereas most other types of crusher use metallic parts to crush rock, the Barmac VSI uses the rock fed into the machine to crush itself. This autogenous crushing process produces the best-shaped aggregate on the market today. The high velocity impact crushing achieved in a Barmac S-Series VSI improves the soundness and shape of stone, reducing product moisture and easing the screening task while producing superior products at a minimum cost.

| Model |

Max Feeding (mm) |

Rotation speed

(r/min)

|

Power (kw) |

Capacity

(t/h)

|

Weight

(t)

|

| S-5 | 30 | 2258-2600 | 30-45 | 30-60 | 4.78 |

| S-7 | 35 | 1775-2050 | 55-110 | 55-120 | 7.50 |

| S-8 | 50 | 1460-1720 | 150-264 | 113-240 | 11.68 |

| S-10 | 60 | 1242-1460 | 320-500 | 220-500 | 17.20 |

| S-11 | 55 | 1401-1677 | 400-500 | 445-600 | 14.8 |

| S-12 | 60 | 1000-1350 | 500-630 | 300-700 | 20.15 |

| S-18 | 76 | 800-1400 | 630-800 | 550-2080 | 32.3 |

NOTE: The above production capacity is based on rocks with a loose specific gravity of 1.6t/m³. In addition, the production capacity of the sand making machine will vary with the feed size, gradation, moisture, and rock type. Therefore, please consult us for specific application.

-

Agency and agent all ovr the world

Agency and agent all ovr the world

White Lai have many office in main market , and services to the customers face-to-face. -

Wear parts supply whole year

Wear parts supply whole year

White Lai with most professional wear parts supply system,to meet the market demand for services effectively.

-

The top services to you

The top services to you

White Lai's after-service number is 0086-21-68768882, 24 hours technical support by e-mail, by phone. -

The first-class customer service

The first-class customer service

If needed,experienced technicians guidance is available anytime. -

Technical support whole day

Technical support whole day

White Lai has service team , guidence with maintenance , spare parts , technical service work ,ect.

Please Feel free to give your inquiry in the form below.We will reply you in 24 hours.